Condition monitoring techniques to detect early signs of changes in lubrication

Detect the wear particles in lubricant generated in the sliding/contact parts such as bearings and gears, then identifying the condition of target portion by analyzing the wear particle morphology, size, concentration, colour and composition. As comprehensively evaluating them, diagnose the degradation condition, identifying wear parts and remaining life. This is the essential diagnostic technique of machines for CBM, such as identifying of optimal overhaul time, increasing of operation availability, reduction of maintenance costs and early detection of abnormal signs. It enables to know the condition of machines in a short time without overhaul, furthermore not necessary to stop facilities for TRIBODIAGNOSIS.

We have been carrying out TRIBODIAGNOSIS more than 20 years and providing a reliable diagnosis based on extensive experience, expertize and accumulated data. It is widely utilized mainly in electric power companies as a key technology for reviewing of overhaul demand or extension of periodic maintenance.

Detect the wear particles in lubricant generated in the sliding/contact parts such as bearings and gears, then identifying the condition of target portion by analyzing the wear particle morphology, size, concentration, colour and composition. As comprehensively evaluating them, diagnose the degradation condition, identifying wear parts and remaining life. This is the essential diagnostic technique of machines for CBM, such as identifying of optimal overhaul time, increasing of operation availability, reduction of maintenance costs and early detection of abnormal signs. It enables to know the condition of machines in a short time without overhaul, furthermore not necessary to stop facilities for TRIBODIAGNOSIS.

We have been carrying out TRIBODIAGNOSIS more than 20 years and providing a reliable diagnosis based on extensive experience, expertize and accumulated data. It is widely utilized mainly in electric power companies as a key technology for reviewing of overhaul demand or extension of periodic maintenance.

TRIBODIAGNOSIS is not only to detect early signs of changes in lubrication condition, but also useful for diagnostic confirmation of the health of machines.

If it has been carrying out as regular checkups from the start of operation, the trend-lines of condition changes will be available for each machines.

In other words, it enables to reduce maintenance costs effectively through trend management.

TRIBODIAGNOSIS catches a minute change of lubrication condition and achieves an effective condition monitoring.

If it has been carrying out as regular checkups from the start of operation, the trend-lines of condition changes will be available for each machines.

In other words, it enables to reduce maintenance costs effectively through trend management.

TRIBODIAGNOSIS catches a minute change of lubrication condition and achieves an effective condition monitoring.

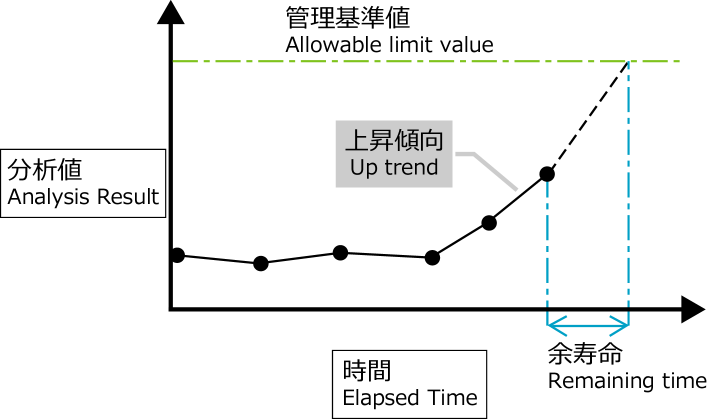

Predict the remaining life of the target machine

A trend management brings the remaining life prediction.

To predict the remaining operation time to reach the threshold by detecting the point of deterioration trend of the target machine, which is set an allowable limit value.

As TRIBODIAGNOSIS is possible to detect the deterioration trend earlier than other condition monitoring techniques, it means that predicting the remaining life is also earlier.

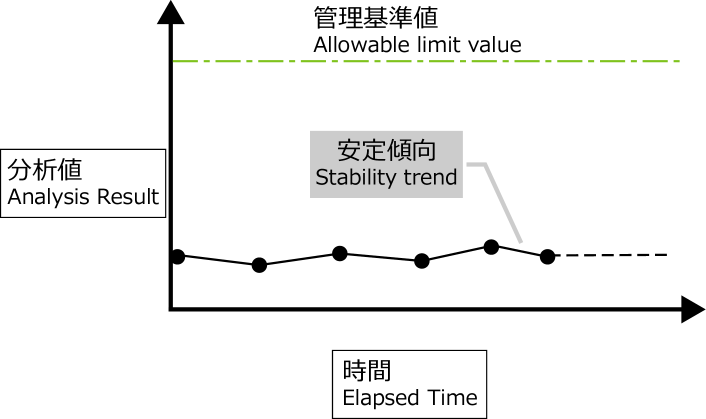

※ The prediction is difficult in the period whilst the analysis result is in stable.

A trend management brings the remaining life prediction.

To predict the remaining operation time to reach the threshold by detecting the point of deterioration trend of the target machine, which is set an allowable limit value.

As TRIBODIAGNOSIS is possible to detect the deterioration trend earlier than other condition monitoring techniques, it means that predicting the remaining life is also earlier.

※ The prediction is difficult in the period whilst the analysis result is in stable.

Remaining life prediction by TRIBODIAGNOSIS

Prediction is difficult in the stable condition

We offer a variety of types of TRIBODAIGNOSIS as diagnostic purpose.

・ Single-item analysis is available

・ Analysis not listed on the contents are available.

・ Standard due date is six business days*. If hurry, please contact us.

・ Any questions about a combination of items, types of TRIBODAIGNOSIS, et al. please feel free to contact us.

*Depends on the number of samples or the requirements, the due date may be more than six business days.

・ Single-item analysis is available

・ Analysis not listed on the contents are available.

・ Standard due date is six business days*. If hurry, please contact us.

・ Any questions about a combination of items, types of TRIBODAIGNOSIS, et al. please feel free to contact us.

*Depends on the number of samples or the requirements, the due date may be more than six business days.

Comprehensive Evaluation / Detailed Diagnosis

・ Wear(incl. option) + Property or Contami or required items

Property - Oil

・ Viscosity (40℃ / 100℃ / Index)

・ TAN

・ TBN (engine oil)

・ IR

・ Oxidation Stability

・ Viscosity (40℃ / 100℃ / Index)

・ TAN

・ TBN (engine oil)

・ IR

・ Oxidation Stability

Property - Grease

・ Consistency

・ Dripping Point

・ TAN

・ IR

・ Consistency

・ Dripping Point

・ TAN

・ IR

Contamination

・ Particle Contamination

・ Contamination by gravimetric

・ Particle Distribution

・ Water

・ Optical Micrograph

・ Particle Contamination

・ Contamination by gravimetric

・ Particle Distribution

・ Water

・ Optical Micrograph

Wear - Oil or Grease

・ Ferrography

・ SOAP-T

[option]

・ Scanning Electron Micrograph

・ X-ray Micro Analysis

・ Ferrography

・ SOAP-T

[option]

・ Scanning Electron Micrograph

・ X-ray Micro Analysis

Representing contents of analysis for TRIBODIAGNOSIS

| Analysis Contents | Measure | Standard | Purpose | |

| Viscosity | mm2/s | JIS K 2283 | ① Lubricant degradation ② Presence of mixture ③ Lubricant property |

|

| Water | ppm | JIS K 2275 | Water content | |

| Acid Number | mgKOH/g | JIS K 2501 | Acid component | |

| Particle Contamination | N/100ml | JIS B 9930 ( NAS1638 ) |

Number of particles by size | |

| Contaminations by Gravimetric Method |

mg/100ml | JIS B 9931 | Mass of insoluble contaminants | |

| Optical Micrograph | ― | ― | Observing of contaminants | |

| Infrared absorption spectroscopy ( IR ) |

%T,cm-1 | JIS K 0117 ( general ) |

① Identification of organics ② Residual volume of antioxidants ③ Oxidation degradations |

|

| Rotary Bomb Oxidation Stability Testing | min | JIS K 2514 | Remaining life of oil | |

| Ferrography | DR | %/ml | ― | Severity of wear |

| Analytical | ― | ― | Causes and points of wear | |

| Spectrometric Oil Analysis Program ( SOAP-T ) |

ppm | JIS K 0116 ( general ) |

Detailed analysis of metal elements and its concentration | |

| Scanning Electron Micrograph ( SEM ) |

― | ― | Detailed Observation of shape of wear particles and inorganics (mainly metals) | |

| X-ray Micro Analysis ( XMA ) |

― | ― | Identifying materials of wear particles and inorganics (mainly metals) | |

| ※For Grease's [Ferrography] [SOAP], preprocessing required such as the dilution, et al. | ||||

Available for the analyse items not listed above. Contact us

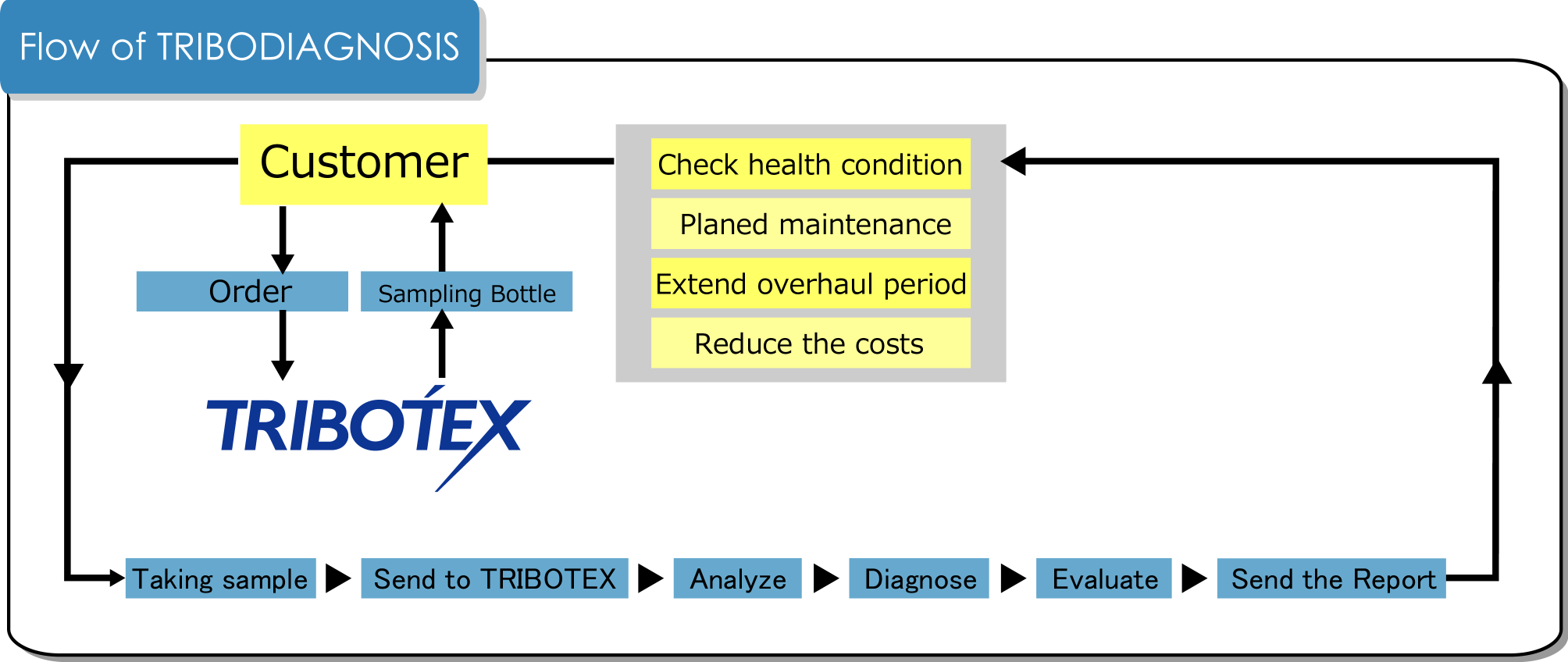

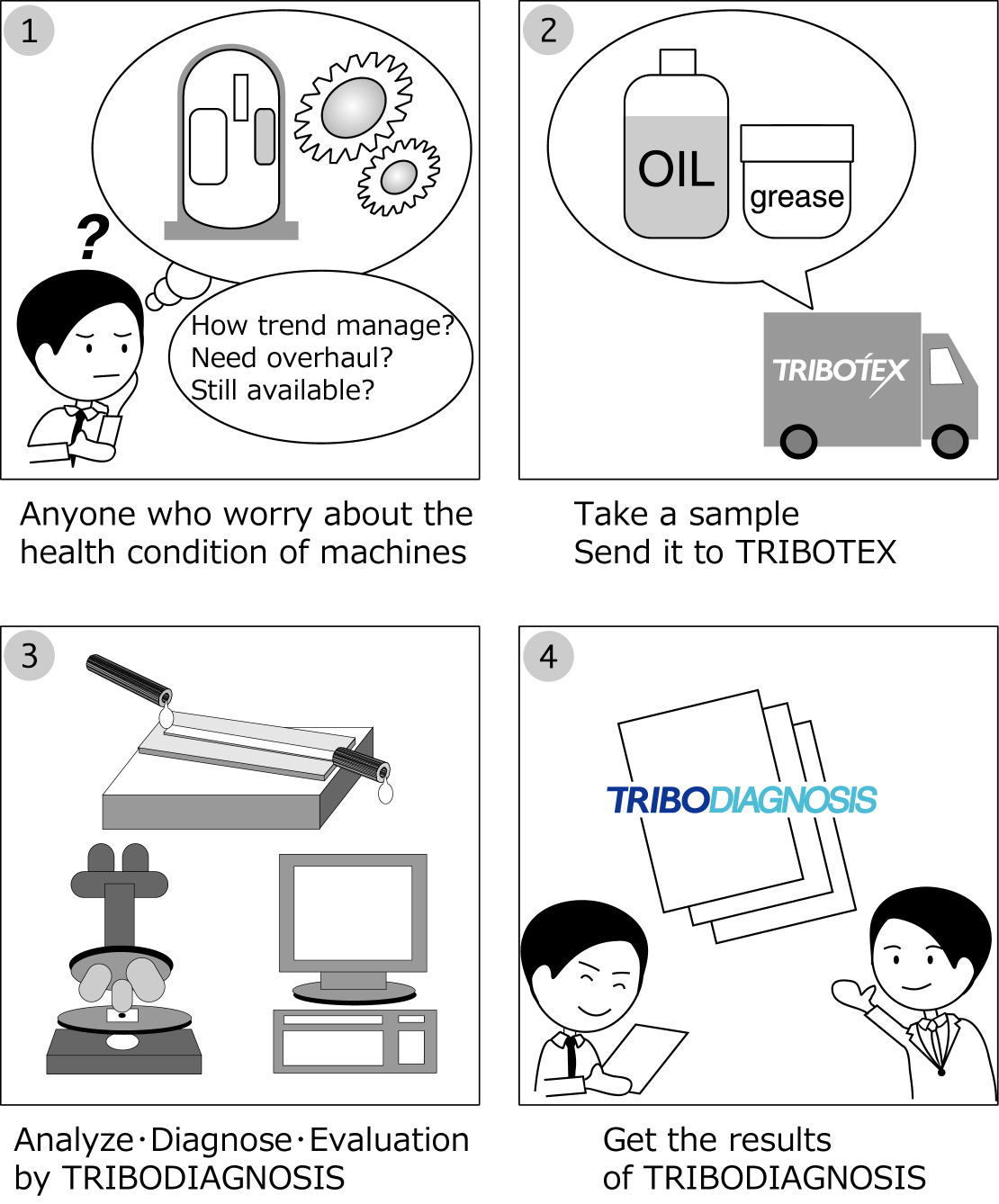

Flow of TRIBODIAGNOSIS

Flow of TRIBODIAGNOSIS

1. Take a sample of lubricant from the target equipment

2. Send the sampled lubricant to TRIBOTEX

3. The sample is analyzed at TRIBOTEX

The target equipment's condition is diagnosed on analyzed data

4. TRIBODIAGNOSIS report is sent to the customer

1. Take a sample of lubricant from the target equipment

2. Send the sampled lubricant to TRIBOTEX

3. The sample is analyzed at TRIBOTEX

The target equipment's condition is diagnosed on analyzed data

4. TRIBODIAGNOSIS report is sent to the customer